Overview

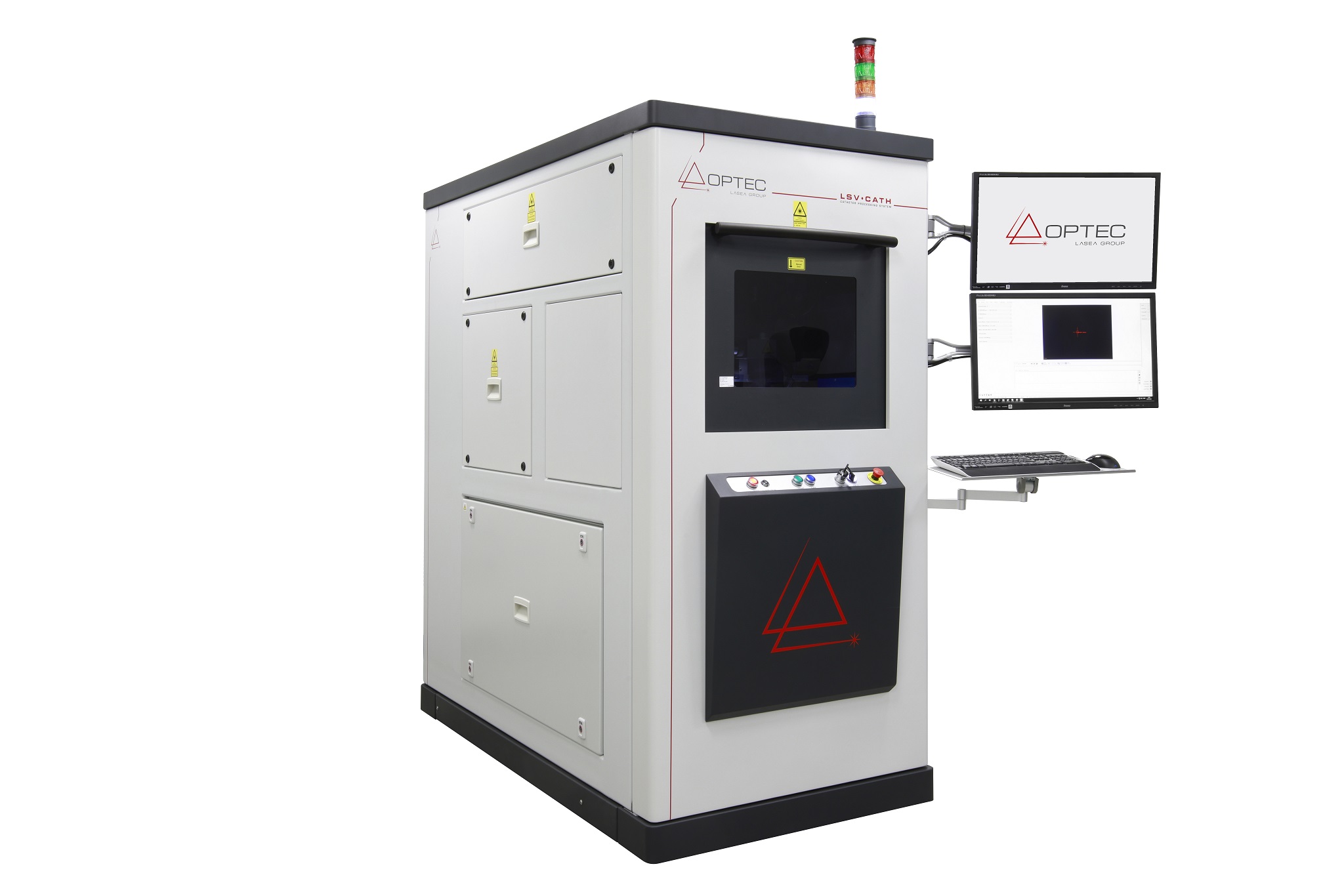

The LASEA laser systems are tailor-made for seamless integration into various workstations or specific customer environments. Our specialized teams in mechanical, electrical, electronic, software, and automation design create solutions based on precise specifications, working independently or with selected partners. Beyond laser technology, we also excel in automation, robotics, vision systems, and human-machine interfaces, offering comprehensive custom machine solutions. No matter the complexity of your project, we are committed to delivering the right solution for successful outcomes.