Overview

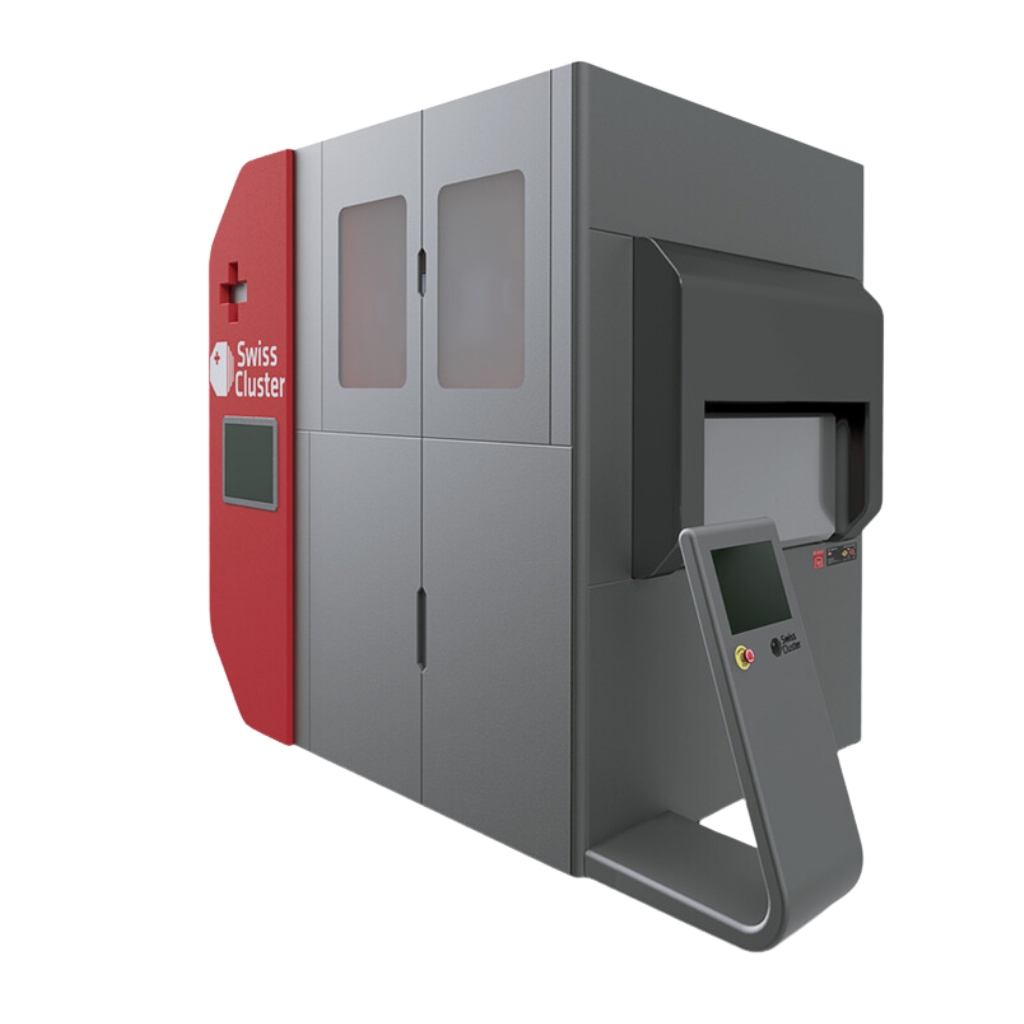

The SC Optima Series is the next generation of large batch systems for Atomic Layer Deposition (ALD). The SC Optima has been carefully optimised to deliver high-quality and uniform coatings to all types of 3D objects in record time, streamlining every step of your door-to door processes, from loading to unloading.

Experience a new level of precision and efficiency in 3D part coating with the

new patent-pending chamber from Swiss Cluster. The innovative and scalable

chamber has been optimally designed to adapt to all types of 3D parts and coating

material to deliver exceptional coating homogeneity at unparalleled process speeds.

Our single chamber approach makes it easy to load and unload 3D parts from

the cleanroom, while the rest of the system is accessed from the grey room. This also

allows for ultra-fast heating and cooling of both the chamber walls and the parts

themselves.